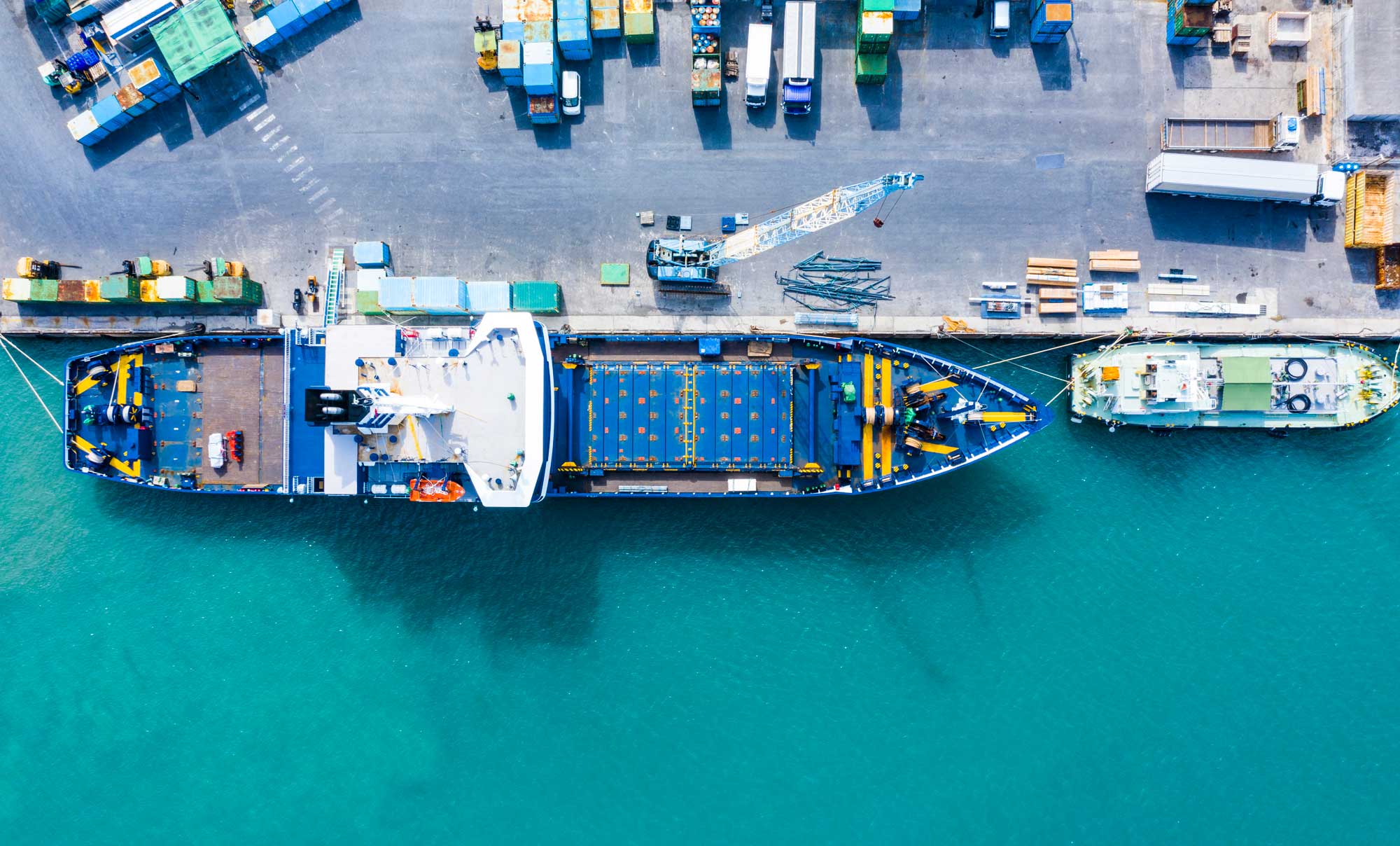

On the 30th of November 2023, the ARA Group acquired Gladstone Fire extinguishers, expanding on our marine and fire services. Gladstone will continue to trade as Gladstone Fire Extinguishers (GFE) within ARA Marine.

We provide routine scheduled testing of fire extinguishers, fire blankets and hose reels as prescribed in AS/NZS 1851.

We ensure your equipment is maintained and ready to use in an emergency situation. We advice on which extinguishers best suit your risk area.

We offer a range of portable fire extinguishers to suit all types and classes of fires.

Dry Chemical Powder Extinguishers

Dry chemical powder fire extinguishers have a white coloured band around the top of the cylinder. Powder fire extinguishers are ideal for use in mixed risk environments and offer all round fire protection. They are classed as safe for electrical fires and are rugged and economical.

Their main disadvantage is the fine powder residue which can be corrosive to electrical equipment,(if to be used near electrical equipment then a clean agent Carbon Dioxide fire extinguisher would be recommended).

CO2 Extinguishers

CO2 is a clean agent extinguisher that leaves no residue behind so it is safer to use around electronic equipment as it can provide fire protection without risking further damage.

They can be a bit more costly than Dry Chemical powder extinguishers but are very effective in helping to keep expensive electronic equipment safe.

Water & Foam Extinguishers

Foam fire extinguishers are ideal for use on fires involving solid combustible materials and are highly effective on flammable liquid fires. The layer of foam applied by these extinguishers helps to prevent re-ignition after the fire has been extinguished. They are not suitable for electrical fires.

Water extinguishers are only suitable for Class A fires such as grass, paper and wood are not suitable for electrical fires.

Hydrostatic Testing

ARA Marine provides hydrostatic testing solutions to ensure that your marine operations are backed by the highest standards of safety and reliability.

At ARA Marine, we are at the forefront of enhancing marine safety compliance with our array of technical services, prominently featuring hydrostatic testing. Hydrostatic testing stands as a crucial procedure, indispensable for verifying the integrity and safety of pressure vessels in marine environments. This includes critical systems like breathing air systems, firefighting equipment, and other essential marine safety devices.

We also have cylinder fill stations which are filled with the following:

• breathing air

• CO2

• nitrogen

The Hydrostatic Testing Process

The core of hydrostatic testing involves filling the vessel with water and subjecting it to a specified pressure level, meticulously examining for any leaks or structural vulnerabilities. This process is not just a routine check; it’s a comprehensive assurance of the component’s ability to endure the real-world pressures of the marine environment. It’s a testament to the safety and dependability of the equipment.